|

Electronic Design |

|

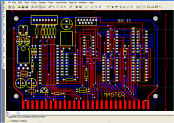

PCB DESIGN |

|

CONTROLLER DESIGN |

|

SUB-SYSTEM DESIGN |

|

(619) 721-0402 |

|

Copyright - Echazarreta Systems - 2019 |

|

PCB DEVELOPMENT FOR ELECTRONIC DESIGN Schematic entry, PCB layout design, Gerber files and Manufacturing drawings are at the heart of the electronic design process. We develop them with strict compliance to EMC, ESD, IPC and Safety design standards using the latest electronic design, simulation and modeling CAD tools.

Our PCB layout electronic design services: New Product Development, Engineering Changes, Reverse Engineering, Cost Reductions, Validation & Verification and Quick Turn electronic design prototypes. Our PCB layout electronic design capabilities: Single layer, Double layer, Multilayer, Flexible, High-speed, Impedance controlled, Radio Frequency RF, Ground-Power planes, Backplanes, Thru-hole, SMT and Mixed technology.

The typical PCB layout electronic design tools that we use include Pads, Orcad, Allegro, Altium and CAM350 and we take extreme care in the selection, planning and design of grids, tracks, pads, vias, annular rings, layers, polygons, clearances, placement, routing, silkscreen, solder mask, keep outs, test points, power planes, grounding, panelization, fiducial marks, mounting holes, cut-outs, material, thermal reliefs, footprints and libraries. Our PCB layout electronic design methodology mitigates the typical harmful effects of crosstalk, induction, attenuation, impedance, delays, reflection and ground loops.

CONTROLLER ELECTRONIC DESIGN We support our customers with electronic control design services from concept to market. Our electronic product design and development methodologies are based on the Phase-Gate design concept. We have an extensive proprietary Knowledge base and Electronic Design expert system Engine. The electronic design process can be conducted in a simplified model or in a full-blown and detailed electronic design and development model.

New Product Electronic Design and Development New Electronic Controls are designed according to the best practices of the analog electronic design, digital electronic design and power electronic design techniques. Our analog electronic design expertise include electronic sensors, electronic instrumentation, filtering design and energy conversion design. Our digital electronic design expertise include microprocessors, microcontrollers, DSPs and FPGAs.

Engineering Changes of Electronic Designs Engineering design changes are used to update electronic components, electronic assemblies, electronic manufacturing processes or electronic design documents like design requirements or design specifications. In electronic product design or electronic manufacturing the need for change is driven for design issues, cost reductions, changes in customer design requirements, change in electronic components or electronic manufacturing methods.

We can review and study existing electronic designs and propose process or electronics engineering design changes to mitigate issues like malfunctions, low reliability, electronic component obsolescence or performance degradation. We can review and study existing electronic designs and propose electronics engineering design changes to increase the electronic features and the designed functions.

Reverse Engineering of existing Electronic Designs Reverse engineering is the process of finding the design principle of a device or a system by analyzing its structure and operation. We provide reverse engineering services of existing electronic designs to deal with the typical reasons for reverse engineering of electronic devices like: Electronic interoperability, lost electronic design documentation, electronic product analysis, electronic design update or correction to match an “as-built” condition, electronic design security auditing, learning about competitor’s electronic design techniques, academic electronic design learning purposes, electronic design technical intelligence, learning from others’ design mistakes or for backward compatibility electronic design analysis.

Technology conversions of Electronic designs Thru-hole to SMT electronic design conversions: Thru-hole electronic components are being obsoleted by component manufacturers. This originates a big issue for old electronic designs. The sourcing of thru-hole parts is becoming more difficult every year and the cost of the components higher. Thru-hole to SMT electronic design conversions are in demand as part of cost reduction and sustaining activities. We have the experience and the tools to complete electronic design conversions with the lowest final cost.

Analog to Digital electronic design conversions: Legacy electronic designs are typically analog. The analog electronic designs are prone to issues like electrical noise, high EMC footprint, bulk components, close to be obsolete components, high power consumption, large PCB dimensions and high manufacturing cost among others. Analog to digital electronic design conversions are in demand as part of cost reductions, sustaining, performance improvement or platform upgrade initiatives. We have the experience and the tools to complete analog to digital electronic design conversions with the lowest final cost.

SUB-SYSTEM ELECTRONIC DESIGN A sub-system/sub-assembly is a collection of two or more individually replaceable items to form a larger assembly or system. In large electronic design projects, it can be helpful to breakdown the system into several sub-assemblies like electronics, box/bracket, active devices and harness. We offer sub-system/sub-assembly or complete system electronic design solutions. The integration of controllers, motors/solenoids/fans, harnesses and box/brackets is accomplished in a cost-effective way according to specifications and industry standards.

FIRMWARE DEVELOPMENT FOR ELECTRONIC DESIGNS The IEEE Firmware definition according to Std 610.12-1990: “The combination of a hardware device and computing instructions that reside as read-only on that device”. The firmware for electronic designs lives in the gray area between electronic hardware and software without strict boundaries. We complement our electronic design expertise with our extensive experience in firmware development. Developed in assembler or C and with strict adherence to coding guidelines and standards like MISRA. Additionally, we use extensively the latest development tools in combination with version control software. Our expertise includes the typical electronic design firmware building blocks like communication protocols, state machines, multitasking, device drivers, memory management, I/O management, error handling, timing, networking and RTOS.

|

|

RADIO FREQUENCY

· WiFi · Bluetooth · RFID · Zigbee · Wireless LAN · Remote Control

|

|

STORAGE & MEMORY

· SD CARDS · SSDD · RAM · ROM · FLASH · USB

|

|

POWER SUPPLY

· AC Power · DC Power · Linear · SMPS · Battery · UPS

|

|

MODULES

· WiFi · GPS · Accelerometer · RF · User Interface

|

|

BACKPLANE BUS

· AdvancedTCA · Comm Express · Compact PCI · PC104 · VME

|

|

PC BUS

· RS232 · PCI · PCIe · SATA · EISA

|

|

CIRCUIT PROTECTION

· Overload · ESD · Lighting · Isolation · PTC · MOV · Fuse |

|

SERIAL COMMUNICATION

· RS232 · RS485 · I2C · SPI · ETHERNET · USB · CAN

|

|

PROCESSING

· CPUs · Microcontroller · DSP · FPGA · SoC · ASIC · CoM |

|

ELECTRONIC DESIGN SERVICES AT COMPETITIVE COSTS FROM CONCEPT TO MARKET ON HARDWARE, FIRMWARE AND SOFTWARE SOLUTIONS. Our new electronic product development methodologies are based on the Phase-Gate concept. We use high level electronic design methodologies and have extensive design and project management experience. We offer objective and quantifiable value to our customers in the form of experience, expertise, authority, low cost, quick, and flexible electronic design services.

ELECTRONIC DESIGN BUILDING BLOCKS AND COMPONENTS EXPERIENCE:

|